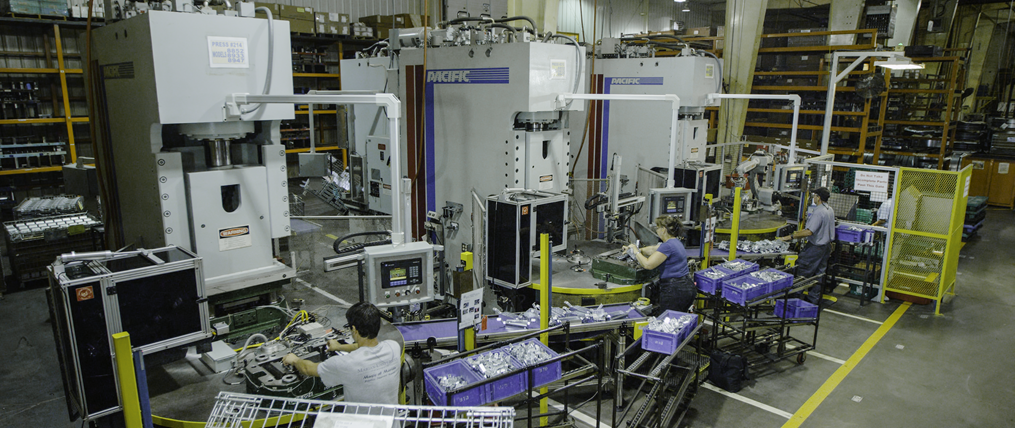

Assembly & Finishing Services

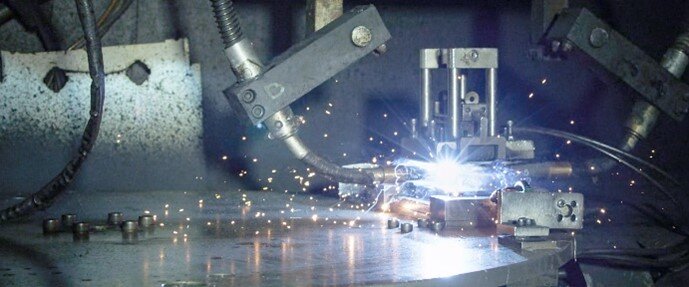

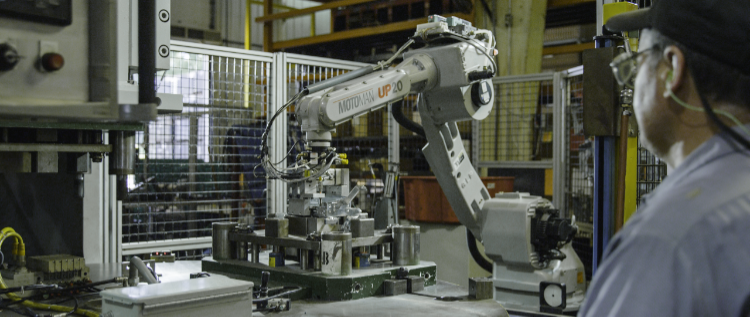

As part of our metal part assembly and finishing services, Batesville Tool & Die offers manual and robotic welding processes for assembling part components of many sizes, shapes, and weights. Our services include the following weld processes in both automated and semi-manual operations for our client needs:

Resistance / Spot welding: Welding of overlapping metal parts at small points by applying pressure and electric current for a set time.

Projection welding: A modification of spot welding where we preform dimpled projections on one of the metal parts by concentrating heat at the projections, using pressure for a short period of time.

Metal Inert Gas Welding (MIG Welding): A semi-automatic or automatic arc welding process in which we feed a continuous and consumable wire electrode and shielding gas through a welding gun creating a bead of weld, fusing the two components together.

For companies that desire completed parts including post metal treatments, Batesville Tool & Die offers a variety of finishing services to improve quality, corrosion resistance and visual appearance per customer requirements.

Some of the metal finishing services we offer include:

Plating

Cleaning/Deburring

Over molded stampings

E-Coat

Powder coating

Heat treating

We strive to be your one stop for all your metal component needs.